Chubo is excited to take you inside the workshops of knife craftsman in Sakai, Japan, who are still making knives completely by hand. Each knife is forged and crafted in the tradition of generations of Japanese blacksmiths. This is the second part of a two part series on the forging of these traditional knives.

Edge Crafting

After completing the forging, hammering, shaping and tempering, each blade is ready to have its edge crafted. This is done by hand on a series of sharpening wheels, starting from rough grit, moving to medium grit and then on to fine grit. Each blade is then sharpened by hand on natural fine grit sharpening stones to refine and hone the edge and bring it to its desired sharpness. This is a delicate process that takes years to master.

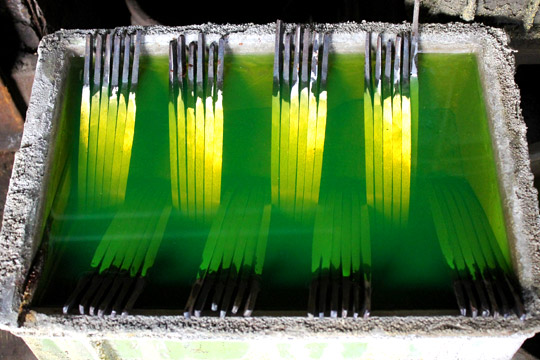

Knives are stored in anti-rusting liquid before the edge crafting process.

Master Sharpener Oda checks the wheel for flatness.

Master Sharpener Oda puts the final sharpening touches on a deba knife.

Handling

The final step in the knife making process is attaching the handle. The handles on traditional knives are made out of high grade Japanese magnolia, a hardwood, that is light, difficult to crack and resistant to water. Each handle is cut to size depending on the knife and is bolster fitted with water buffalo horn. The last step is to heat the tang of the knife and insert and hammer into the handle.

The craftsman cuts the magnolia handles to size.

Each handle is fitted with a piece of water buffalo horn.

The handle is attached to the knife and it is now ready to be used.