We had the honor of sitting down with Shosui Takeda, the owner of Takeda Knives. Takedas’ blue steel knives are highly regarded for their craftsmanship, long lasting sharpness and overall superior performance.

How long have you been making knives and how did you start?

Because my father was also a blacksmith, I started helping out around the workshop when I was an elementary school student. At that time, my goal was to earn some allowance money to go bowling. Honestly though, it was never my intention to follow in my father’s footsteps and I didn’t start truly working as a blacksmith until I was 28.

How has your knife making progressed over the years?

The reason I started to make knives with a very thin blade was because of some comments from a long time customer. He told me “your knives hold a great edge, but the blade is too thick for cutting thick root vegetables like daikon without breaking the vegetable. Can you make your blades thinner?”. These comments twenty years ago changed my approach to knife making. Even after twenty six years of knife making, I still don’t know what the perfect knife is and all I can do is my absolute best every time. I still haven’t produced a knife that I’m one hundred percent happy with.

What are the traits of a good knife to you?

There are so many factors that make a great knife. To name a few: great cutting feel which lasts over time, easy to use, doesn’t chip or get damaged easily, can use for many years, difficult to rust, easy to sharpen. Also, I want our knives to cost the same as what you’d invest in a special pair of shoes. I could go on and on, but these are the basic things I think about every day when I’m in the workshop making knives.

Why do you choose to use Aogami Super Blue Steel? What makes it so special?

As far as the Aogami Super, all of our customers would only choose Aogami Super after using that knife. They say that they just can’t go back to other types of steel. About twenty years ago when we first started using Aogami Super, our main material was Blue Steel #1. Even though those knives held a great edge and were half the price, customers were choosing the Aogami Super. It’s that simple. From a craftsmanship perspective, when I first forged with Aogami Super, it was obvious that is a very very difficult material to work with. Even at this point, it is much harder than using a steel which is just one rank down. I do end up with a higher percentage of failed blades than I would working with other types of steel, but I feel it’s worth it for the end result.

You use a rosewood handle on your knives instead of magnolia. What are the benefits?

Rosewood is much tougher than magnolia. Repairing knives is an important part of what we do and we get knives back that have been used for twenty years. We can see that the rosewood lasts well over time even in professional kitchens. Shapewise, I do feel that the octagonal shape is the most comfortable and can be used by anyone. There are all kinds of different designs out there, but I believe the octagonal handles are the best.

Which of your knives are popular (overseas and Japan) and do you have any plans for new models in the future?

We’ve never once had our own idea of ‘producing a new model’. The reason our knife collection grows over time is all based on customer requests and feedback. We make changes to our knives little by little over time based on these comments.

What is your philosophy towards craftsmanship?

Something that I’ve discovered recently is a true craftsman is a person who doesn’t think in a sales related way. For example, if you think of all the different processes available for knife making, you see there are many ways to make knives that are profitable and easy to sell. You can make knives with press cutters or lasers, use layered steel or have a polished blade. These processes don’t require as much work. But when you have to make a decision on which process to use, a true craftsman chooses the method which creates the best knife for the user. Even if this process means more work to make and sell the knife, this is the path I will always choose. My goal is to pursue the best quality no matter what.

What is the process of forging a knife?

We start out by ordering a type of Aogami Super Blue steel called ‘fukugokouzai’. This combines carbon steel and a soft carbon blend. I feel this is the best quality material to start with.

Next, we cut the materials into the shape of each knife and weld the ‘nakago’ (tang) to each blade. We use a stain resistant steel for the nakago, so there won’t be any corrosion inside the handle of the knife. After welding these two pieces together, I use a hand grinder to smooth the joint between the nakago and body of the knife. Each knife then goes through a multiple-step forging and heat treatment process.

We then reshape each knife with a grinder and use a belt sander to smooth the edges step by step. At this point, we double check the joint between the nakago and the body of the knife. If there is even a slight imperfection, we re-weld and regrind the joint until it’s perfect.

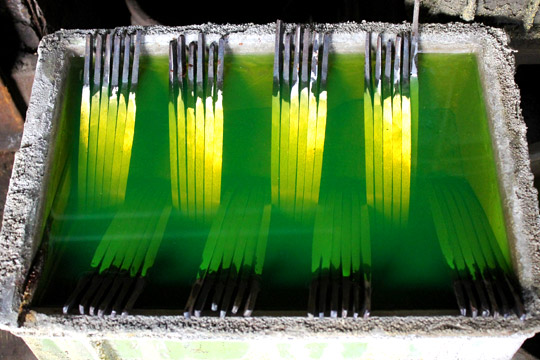

We put a starter edge on to each knife and clean the surface of each blade with a wire brush. The knife is now ready for ‘yaki-ire’, a very important three day heating and cooling process.

To prep each knife for yaki-ire, we coat the blade with a powder made of natural sharpening stones and pine charcoal. In my furnace, I heat lead to 820 degrees Celsius and put each knife one by one into the furnace until it glows the appropriate ‘red’. Once the color is just right, I plunge the knife into an oil bath to cool it and clean it with a wire brush to remove any powder residue.

I have a tub with hot oil, set to 150 degrees Celsius, which each knife goes into after the ‘yaki-ire’ process. At the end of the day, the tub holds all of the knives I’ve worked on. I then heat the oil to 170 degrees Celsius and keep it at that temperature for forty minutes. I let the knives cool and sit in the tub overnight.

The next morning I heat the oil to 170 degrees again and keep it at that temperature for forty minutes. The knives sit in the tub for another twenty four hours. Lastly, I heat the oil to 150 degrees, take out each knife one by one and clean it with wood shavings.

After ‘yaki-ire’, I make sure each knife blade is completely straight.

Next is the edge crafting process. I start out using a ‘san-shaku’ rough grit sharpening wheel and then move onto a flat rotation medium grit sharpening wheel. The final process is to sharpen each knife by hand on a series of sharpening stones and coat with an anti-rusting material.

Lastly, we need to attach the handle. We insert epoxy into each handle and insert the blade, adjusting to the correct angle. The knife is now ready to be boxed up and leave our workshop!